Food Safety Planning for Craft Brewers

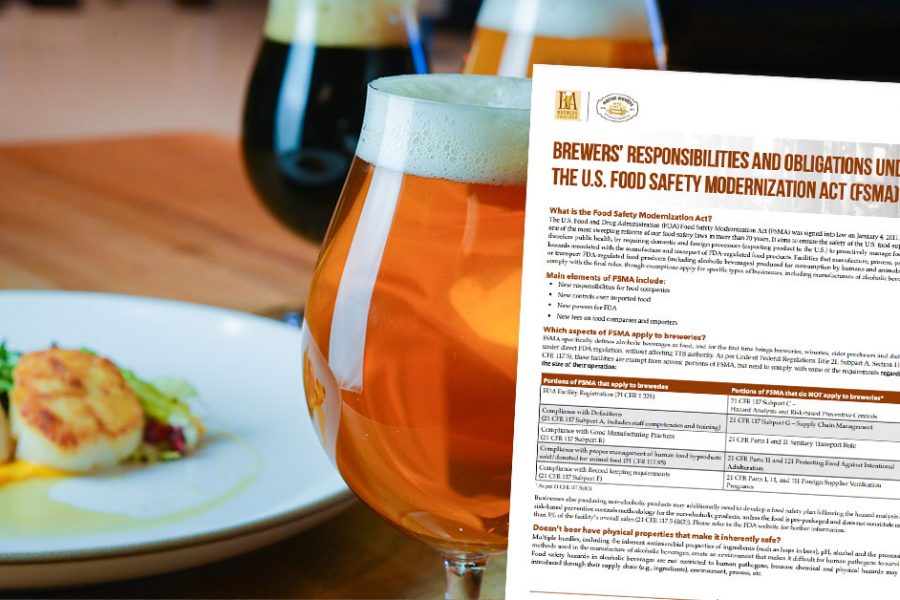

Familiarize yourself with the requirements of the Food Safety Modernization Act (FSMA) and learn practical guidance on implementing FSMA requirements.Read More

You are using an outdated browser not supported by The Brewers Association.

Please consider upgrading!

For many years, breweries have leaned on the assertion that there are no known pathogens (bacteria, viruses or other microorganisms that can cause disease) that can survive in beer. While many studies have shown beer to be an inhospitable environment for many microorganisms, it is important to understand that potential food safety hazards are not limited to pathogens. Potential threats include chemical and physical hazards which could harm a consumer. It is the responsibility of the brewer to ensure that they have taken all necessary measures to identify and prevent all potential hazards.

Familiarize yourself with the requirements of the Food Safety Modernization Act (FSMA) and learn practical guidance on implementing FSMA requirements.Read More

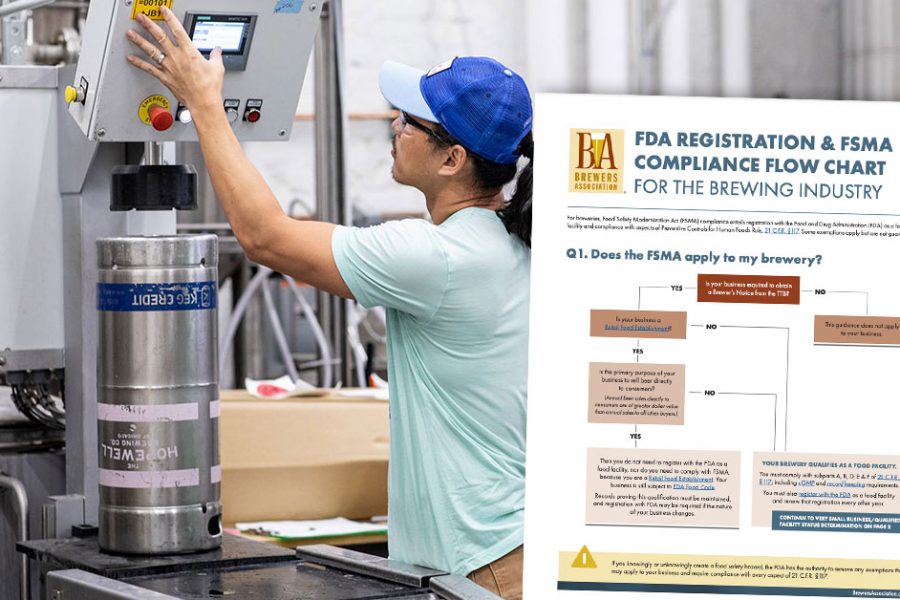

This flow chart will help you to navigate through the rules and definitions in FSMA, as well as suggest food safety best practices.Read More

What is a voluntary market withdrawal or recall and what are some of the reasons they would be necessary? Learn what steps to take to prepare your brewery.Read More

The Food Safety Plan for Craft Brewers provides guidance for craft breweries to design and implement a food safety program.Read More

Brewing a non-alcohol (NA) beer can be challenging from a flavor standpoint, but the lack of alcohol also creates food safety considerations that are separate from alcohol-containing beers.

There are challenges to not just producing and packaging food-safe non-alcohol (NA) beer, but extra considerations crucial to NA on draught.Read More

Understand the pasteurization unit (PU) calculation, equipment used, validation points, factors affecting PUs, and safety considerations.Read More

This seminar will focus on the three major components of a successful traceability program: labeling, tracking, and practicing tracing.Read More

Contract Brewing: Production Best Practices

Contract Brewing: Production Best Practices

The Quality Subcommittee created a playlist of resources to highlight technical brewing aspects to consider when navigating contract brewing.Read More

Educate your team to be aware of the safety risks and precautions when cleaning beer lines with these training resources.Read More

This document provides a brief overview of the different key considerations brewers must address when producing non-alcohol beer. Read More

Establishing and Expanding Brewery Food Safety Programs

Establishing and Expanding Brewery Food Safety Programs

One stop shop for finding the resources a brewery needs for developing and maintaining a food safety program.Read More

This webinar focuses on the three major components of a successful traceability program: labeling, tracking, and practicing tracing.Read More

Legal, Quality, and Packaging Tips for Shipping Beer Direct-to-Consumer

Legal, Quality, and Packaging Tips for Shipping Beer Direct-to-Consumer

Are you set up to ship beer direct-to-consumer? Check out this playlist for best practices from the BA Quality Subcommittee.Read More