A contractor is a third-party company or person hired to provide materials and/or labor. As a third-party, these folks are not on a brewery’s payroll. Examples of work contractors might be people who perform jobs include heating, ventilation, and air conditioning (HVAC) services, beer line cleaning, boiler maintenance, and staffing events. Contract work can range from a simple daily task to a multi-day work project requiring a general contractor to oversee various subcontractors. This resource will provide information for breweries needing or considering contract work, and the important safety and regulatory considerations when entering into contracted work agreements.

While this resource focuses on outside contractors, it does not provide safety and regulatory information on other types of non-employees sometimes found in a brewery, such as volunteer workers, tour groups, inspectors, delivery trucks, or temporary workers. Check out the linked resources for more information about those specific groups.

Getting the Right Contractor for the Job

When planning a brewery project, it is important to consider and then recognize when the work requires hiring an outside contractor. The best example is electrical work, but there are a variety of highly specialized and potentially hazardous projects brewers will want to hire out.

Projects requiring contractors should be handled by an expert in that field. Brewers should explore multiple options and compare more than just the quotes. Evaluate a contractor’s reputation, certifications or licenses, and how they approach safety. In the long run, it is worth paying more up front to get the project done right and safely the first time than to pay twice to redo a project or, worse, for injuries or incidents.

Questions to Ask a Potential Contractor

Consider asking potential contractors these questions before making a final decision on who to hire for the job:

- What types of insurances do they have and are they sufficient for the project?

- Do they hold the right type of license or certification to perform the work requested?

- Can they answer questions about hazards and safety measures pertinent to the project?

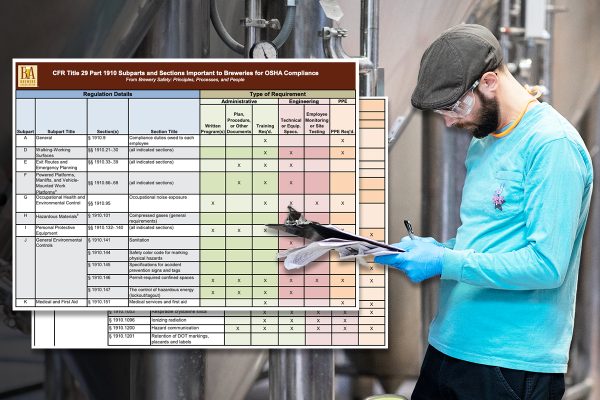

- Are they familiar with regulatory standards regarding the project?

- Will they need to hire subcontractors? If yes, can they provide proof of insurance, certifications, and safety competency of those subcontractors?

Starting Smart with a Contractor

Even if the contractor has done work in a brewery before do not assume they know every hazard in that brewery. Before work begins, provide a safety orientation similar to what a new employee might receive, and cover all pertinent hazard and safety measures. Product sampling policies and expected behaviors should be clearly communicated during the orientation, particularly for those breweries with taprooms onsite. In a multi-employer worksite scenario where employees are reporting to multiple contractors, identify and communicate who the controlling contractor is during the orientation training. Consider the Occupational Safety and Hazard Association’s (OSHA) Multi-Employer Citation Policy for these types of large work projects.

As with all safety training, contractor safety orientation must be documented. Orientation training materials can include, but are not limited to:

- Hazard communication (HAZCOM)

- Emergency action plans

- Burn danger

- Carbon dioxide

- Pressurized vessels

- Lock Out Tag Out (LOTO)

- Confined spaces

- Forklifts and other powered industrial trucks

- Fall protection

- Slips, trips, and falls

- Anything else relevant to your facility and the work project

It is possible the contractor needs to bring in equipment and/or chemicals that introduce new hazards into the brewery. It is the brewer’s responsibility to also educate all brewery employees on these new hazards and, when necessary, provide or enact safety measures to protect against the hazards and document those trainings.

Communication is the most important part of the relationship between a brewery and a contractor. Even if both parties have excellent safety plans and hazard mitigation equipment, these need to be compared and aligned through effective communication before project work begins. When these do not align, all parties should discuss and merge safety protocols and expectation so work can proceed on a unified front. This will often assure a smoother project experience and keep everyone safe.

Responsibility for Regulatory Reporting

The responsibility of recording injury, illness, and fatalities lies with the entity or person who is supervising that employee’s day-to-day activities. Typically, when a brewery is supervising the contractor doing work at their facility it is the responsibility of the brewery to report any injury, illness, or fatality. When a contractor is supervising the work of their employees and the subcontracted employees, the contractor is responsible for reporting all injuries, illness, or fatalities, even if the employees are not on the contractor’s payroll.

OSHA states that “day-to-day supervision occurs when, in addition to specifying the output, product, or result to be accomplished by the person’s work, the employer supervises the details, means, methods and processes by which the work is to be accomplished.”

Finishing Contract Work Strong

Upon project completion, there should be a final walk through with the brewery and contractor. At this point, the brewery should review whether the work was completed fully as outlined in the work project expectations. Ensure that the worked finished does not present new hazards. Get trained on any new equipment that has been installed. Finally, keep records of what was done in case problems show up later.

With anything in the brewing industry, safety and quality go hand-in-hand. In the end, investing in the right person do the job right the first time will save time, money, stress, and keep everyone safe.